Digital transformation in the automotive aftermarket is not just a trend but a necessity. The shift toward digital platforms has reshaped how businesses operate, from inventory management to customer interactions. Within the digital revolution, one fundamental principle remains unchanged: what you see online should be what you get.

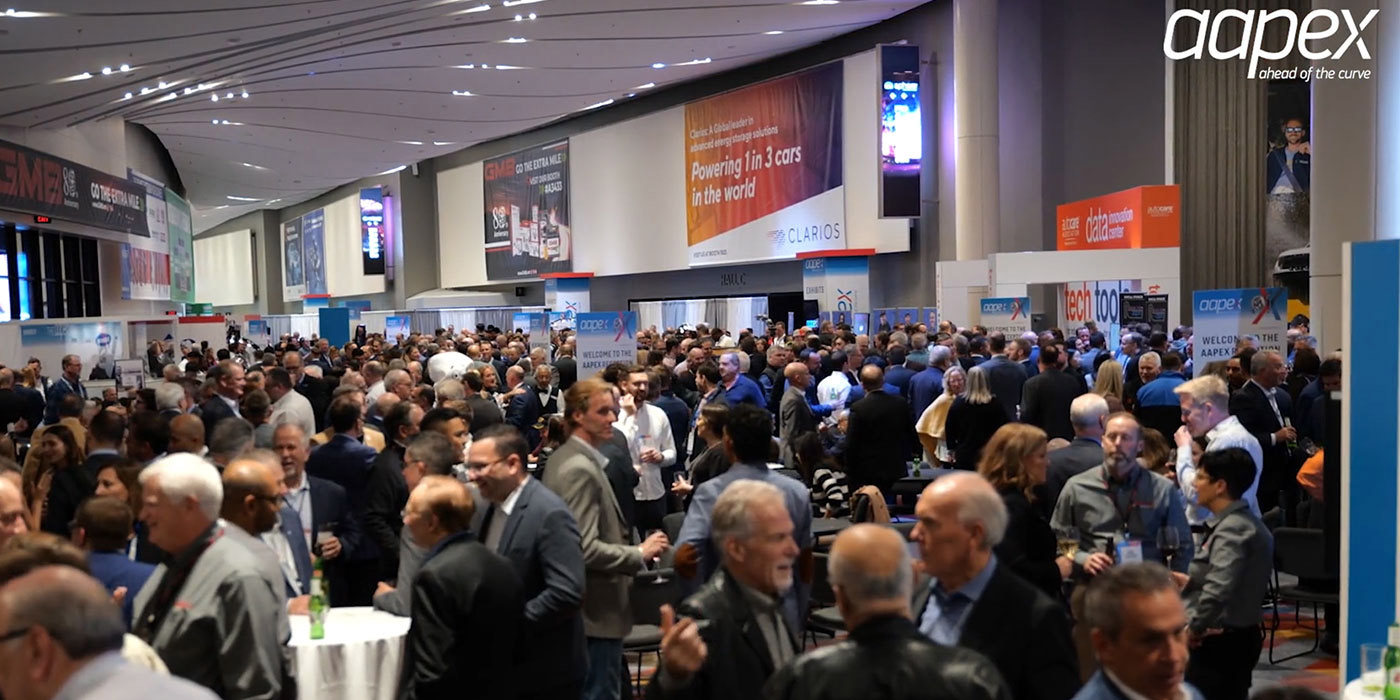

Embracing technology, though challenging, is essential for success. Businesses that have adopted digital tools like online ordering and e-commerce platforms are reaping significant benefits. These companies demonstrate that digital adoption is not merely an option, but a critical factor in achieving success in the competitive automotive aftermarket. At AAPEX, attendees can see firsthand how digital tools enhance accuracy.

Companies will be showcasing digital solutions such as advanced electronic cataloging systems that demonstrate how accurate inventory and product information can streamline operations and reduce errors.

Product availability is another significant challenge in the automotive aftermarket. AAPEX research highlights that this issue is the number one concern for many attendees. Digital tools enable businesses to maintain up-to-date records of available products, ensuring that customers receive what they need, when they need it.

AAPEX serves as a hub for innovative solutions, from digital services to parts and products that drive the automotive aftermarket forward.

Join us at AAPEX this November in Las Vegas to discover the future of the automotive aftermarket.

A special thanks to Jim Franco at Autologue Computer Systems for providing his insights for this video.